When ballasting, the ballast water is filtrated by an automatic back-flushing Filter (AFU), which removes large plankton and solid particles from ballast water. Then, at disinfection stage, a side stream of seawater flows through an electrolytic unit ( EDU ) to produce oxidant (sodium hypochlorite ), which is then injected back into the main ballast pipe to the ballast tanks to sterilize marine organism, such as plankton, pathogens, larva or spores.

When de-ballasting, a neutralizer is added into the treated ballast water to neutralize the residual oxidant (TRO). The neutralization process will always be activated prior to discharge to ensure that de-ballast water complies with IMO D-2 and USCG VGP regulations.

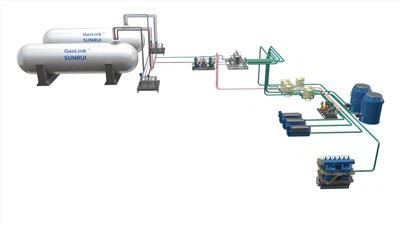

1. Automatic Back-flushing Filter Unit

The ballast filter is an automatic back-flushing filter. Its flushing is done without interrupting operation and with a minimal pressure drop. The filter has a 50 micron screen, which can effectively remove planktons and solid particles whose size exceeds 50 micron and help to reduce the consumption of oxidant generated by the system.

As filtration carries on, the soiling in the filter elements would increase the pressure difference between the filter inlet and outlet. When the differential pressure of the filter screen or the working time achieves the set value, the system will automatically start self-cleaning cycle, and the dirty water is immediately discharged overboard either by the own pressure of the dirty water or by the sludge pump.

2. Electrolytic Disinfection Unit

The electrolytic unit intakes a small part of filtrated seawater to electrolyzer and generates oxidant (mainly sodium hypochlorite) and by-product hydrogen. The electrolyzed water contains sodium hypochlorite solution is injected back into the main ballast pipe with an oxidant dosing pump or unit. The oxidant reacts in the main ballast pipe to provide effective disinfection. The by-product hydrogen is separated by the cyclone and then sufficiently diluted with air by the blower to a safe level before it is released to open air.

Normally, the electrolytic unit takes seawater from AFU outlet or main seawater pipe with a seawater booster pump; for fresh water voyage treatment, APT or other seawater reserving tank will be taken to supply seawater for the electrolytic unit

3. Automatic Neutralization Unit

Automatic neutralization unit is used to neutralizing residual chlorite in the treated ballast water during de-ballasting process. Na2S2O3 solution is used as the neutralizer.

NaCl and Na2SO4 produced in the neutralization reaction are mild chemicals which will not pose risks to receiving waters.

4. Monitoring and Control System

The monitoring and control system is used to monitor and control the whole of operation of BalClor® BWMS. The working status of the components in this system are automatically monitored and controlled through both local and remote control cabinet.

Hot Tags: balclor® ballast water management system, China, manufacturers, suppliers, customized, company, service, project